Introduction To RSP

There is a great history behind the bosun chair and Rope Suspended Platforms (RSP) for work at height. Borne from the sea, the boatswain (bosun) was the ship’s officer responsible for maintaining the sea vessel. They used a wooden seat suspended from rope rigging to access hard to reach areas.

The time changed. The continuous development, lots of modifications and innovations were done and the construction industry started to accept the working of RSP widely. The machines were designed more compact, reliable and safe with many advance features.

In present scenario of construction industry all are fast track projects and time is a chief priority. To survive with the priority, getting skill workmen is very difficult. Hence industry is absolutely depended on new technologies. RSP is a technology used widely by contractors resulting reduction in time and cost of construction.

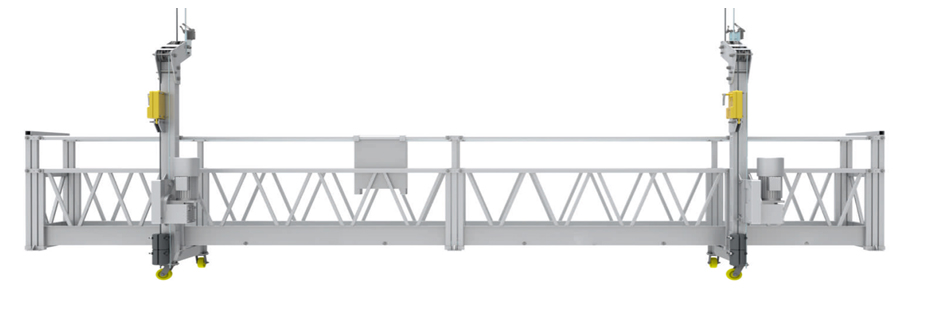

RSP which is commonly known as Gondola (or cradle/ or RSP) is an electrically operated temporarily installed suspended access equipment which is a suspended manned facility for work at heights by relying on a movable platform driven by motors, designed to suspend along the vertical surface of building by steel wire ropes through the suspension mechanism placed at the top of building. It is a kind of non-regular suspended access equipment. The suspended access equipment is featured in strong construction adaptability, higher construction height, less occupation of construction land, high construction efficiency, easy erection, less labour need and etc.

RSP are now widely used in India for working at height for the installation of billboard or windows, window cleaning, external renovation, painting, plastering, decoration of bridges, buildings, chimneys, silos and other structures, etc. This is an easy-to-use and efficient solution. Decades of engineering experience is utilized for developing a safe modular system that makes it easy to quickly adjust the platform’s dimensions and shape to the current needs. When designing and fabricating suspended platforms, the maker focuses on quality and reliability. High quality materials and components guarantee long life cycles, outstanding durability and wear resistance.

The RSP is high-efficiency modern overhead operation equipment capable of replacing a traditional bamboos or metal scaffold and being reused. It is considered as an asset with higher safety and easiness in working. It is a safe machine; lots of advance safety features like digital load cell, anti tilting and anti sway restriction devices are added with the machines. This is easy to install, dismantle, shift and even storage or transportation also. It takes only 1-2 days for installation with minimum numbers of manpower; so there is less dependency on labours. It is permissible to work on height. So now RSP is the key to entry for big projects tendering. There is long life of machine, easy to repair with lower maintenance cost and good resale value also.

Two major groups of suspended working platforms, i.e. permanent suspended working platforms and temporary suspended working platforms.

Permanent Suspended Working Platform:

A permanent suspended working platform is designed especially to be permanently installed on a specific building or structure for the inspection, cleaning and maintenance of the facades. It is also known as a building maintenance unit (BMU). It comprises a working platform suspended by wire ropes from a roof rig, a trolley of the monorail fixed to the building, or a roof trolley. The roof rig may be a fixed structure to which a working platform is attached. The working platform may be lifted and lowered and may be traversed and rotated.

Temporary Suspended Working Platform

A temporary suspended working platform is temporarily assembled on a building or a structure. It will be dismantled at the end of the work for which it was installed. A temporary suspended working platform comprises a working platform, normally suspended on wire ropes attached to a roof rig. The working platform may be lifted or lowered by winches or climbers which are usually mounted on the working platform. Sometimes, the working platform is also designed to traverse. The stability of the roof rig may be achieved either by counterweights (Counter weight mechanism- suspension mechanism) or direct attachment to the structure component (parapet clamping/ wall brackets/ I-beam) of the roof of the building or structure.

Authored by:

RSPian

Santosh Chaurasia